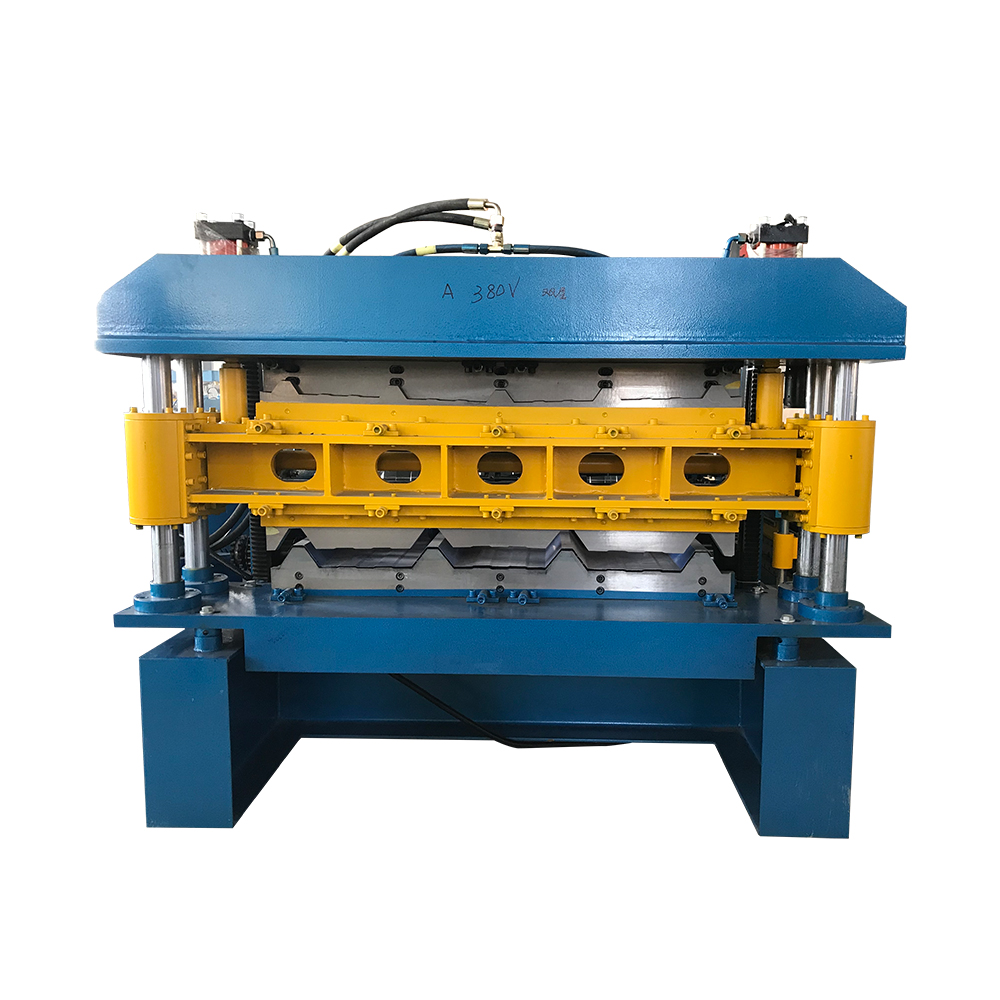

Double layer roll forming machine

Double layer Roll Forming Machine Main Roll Forming System:

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Length of the main part: about 6500х1450х1500

Weight of main part: 3.8 tons

Voltage: 380v 50hz 3 phase

Roller fixer: middle plate

Frame: 500 H steel welded

Drive mode: chain

Material of rollers:45# steel, surface hard chromium plating.

Material of shafts: 45# steel

Diameter of shafts: φ80mm

Number of rollers: 13 rollers

Main power: 5.5kw System

Details of the system

1 Decoiler system

its type has manual decoiler,electric decoiler and hydraulic.

generally the manual decoiler is standared configuration.

Its length is three meters long. It has no active roating ability but economical.

2 Feeding inlet

- adopt stainless lead-in rod can protect the surface of material

- with a set of rubber wheels between rollers can convinent to into the material

- two rows of rubber wheels prevent the material hurting

- with manual broach can easy to cut the material and reduce waste the material

3 Framework

the frame is welded with 500H steel.which is convinent to transport and move.

Generally with raking and flying can make the base stable.

Has lifting eye/legs/holes,easy to transport.

4 Automatic stacker in double layer roll forming machine

Can realize upper automatic picking and automatic reciving,save time and labor.

its length can be customized according to the specific request.

has thicker plate to process from.

Flow work

Our service

a. If buyers visit our factory and check the machine, we will teach you how to install and use the stud and track Roll Forming Machine for sale , and also train your workers/technician face to face.

b. Without visiting, we will send you user manual and video to teach you to install and operate.

c. If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

d. If there is any problem found of steel roof sheet roll forming machinery, we will repair roll forming machine for sale for free in one year.

Contact me

info@geitgroup.com

whatsapp:+86 15612731108

www.geitroofsheetmachine.com